Adopting energy-efficient equipment and strategic workspace optimization are key to eco-friendly collision repair. This includes high-efficiency spray booths, advanced diagnostics, natural light, LED lighting, smart temperature control, and green practices like paperless systems, staff training, electric vehicles, responsible disposal, and supply chain rethinking to minimize environmental impact and contribute to sustainability.

In the realm of eco-friendly collision repair, minimizing energy use isn’t just beneficial—it’s essential. This comprehensive guide explores best practices tailored to transform your workshop into an energy-efficient haven. Discover how utilizing advanced, energy-smart equipment and technology can significantly reduce consumption. Learn strategies for optimizing workspaces and adopting green practices in daily operations. Embrace these methods to not only cut costs but also contribute to a more sustainable future.

- Utilize Energy-Efficient Equipment and Technology

- Optimize Workspaces for Reduced Energy Consumption

- Implement Green Practices in Daily Operations

Utilize Energy-Efficient Equipment and Technology

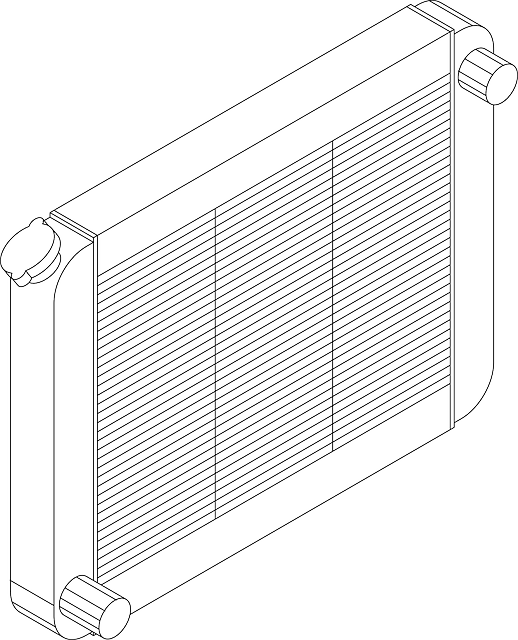

In the realm of eco-friendly collision repair, adopting energy-efficient equipment and technology is a strategic move towards sustainability. Auto collision centers can make significant strides in reducing their environmental footprint by investing in modern tools and machinery designed with energy conservation in mind. For instance, high-efficiency spray booths utilize less energy while providing optimal conditions for painting cars, thereby cutting down on overall power consumption.

Similarly, incorporating advanced diagnostics and computer-aided systems streamlines the repair process at car repair shops. These technologies enable precise assessments, minimizing the need for redundant tests that consume energy. By integrating such innovations, auto body services can achieve a delicate balance between effective repairs and minimal energy usage, contributing to a greener future in collision repair.

Optimize Workspaces for Reduced Energy Consumption

Eco-friendly collision repair shops can significantly reduce their energy consumption by optimizing workspaces for efficiency. This includes strategic placement of equipment and materials to minimize unnecessary movement and energy waste. Well-designed layouts ensure that tools and parts are easily accessible, reducing the time spent searching, which in turn lowers energy usage. Natural lighting should be maximized through large windows and skylights, supplemented by energy-efficient LED lighting where needed, eliminating the reliance on conventional fluorescent lights.

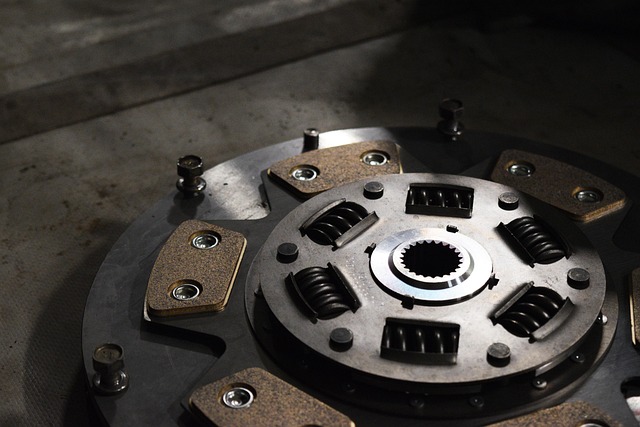

Additionally, implementing smart technology for temperature control, such as programmable thermostats and zone heating/cooling systems, can optimize energy use in collision centers. These innovations allow for precise climate management, preventing excessive heating or cooling. Moreover, integrating high-efficiency machinery and equipment, like electric or hybrid vehicles used for luxury vehicle repair and car dent repair, plays a crucial role in minimizing the environmental impact of collision repair processes within these facilities.

Implement Green Practices in Daily Operations

In eco-friendly collision repair, implementing green practices is not just a trend but a necessary step towards sustainability. Beyond using recycled materials and energy-efficient equipment, everyday operations can significantly reduce environmental impact. For instance, adopting paperless systems streamlines processes, cuts down on waste, and reduces the carbon footprint associated with printing. Additionally, proper training for staff to ensure efficient water usage in cleaning processes and the adoption of electric or hybrid vehicles for transportation within the workshop further contribute to minimizing environmental damage.

A key component of green automotive collision repair involves rethinking supply chains. Sourcing eco-friendly materials and components reduces pollution and waste from production. Encouraging suppliers to adopt sustainable practices creates a ripple effect across the industry, leading to more responsible automotive repair services. Moreover, proper disposal and recycling of hazardous materials like solvents and metals are crucial, ensuring that even minor aspects of a fender bender don’t cause lasting environmental harm.

In the realm of eco-friendly collision repair, adopting best practices for minimizing energy use is not just an environmental responsibility but also a strategic move towards sustainability. By utilizing energy-efficient equipment and technology, optimizing workspaces, and implementing green practices in daily operations, repair facilities can significantly reduce their carbon footprint. These efforts not only contribute to preserving our planet’s resources but also foster a reputation as industry leaders in responsible business practices. Embracing these strategies is a step towards a greener future for the collision repair sector.